Bringing the world closer with sustainable supersonic travel.

Time and distance overcome.

With their twice-as-fast aviation technology, Boom aims to enable same-day round trips for distant meetings, allow global leaders to address crises in person, and unlock new opportunities for human connection.

Innovative software to support innovative hardware.

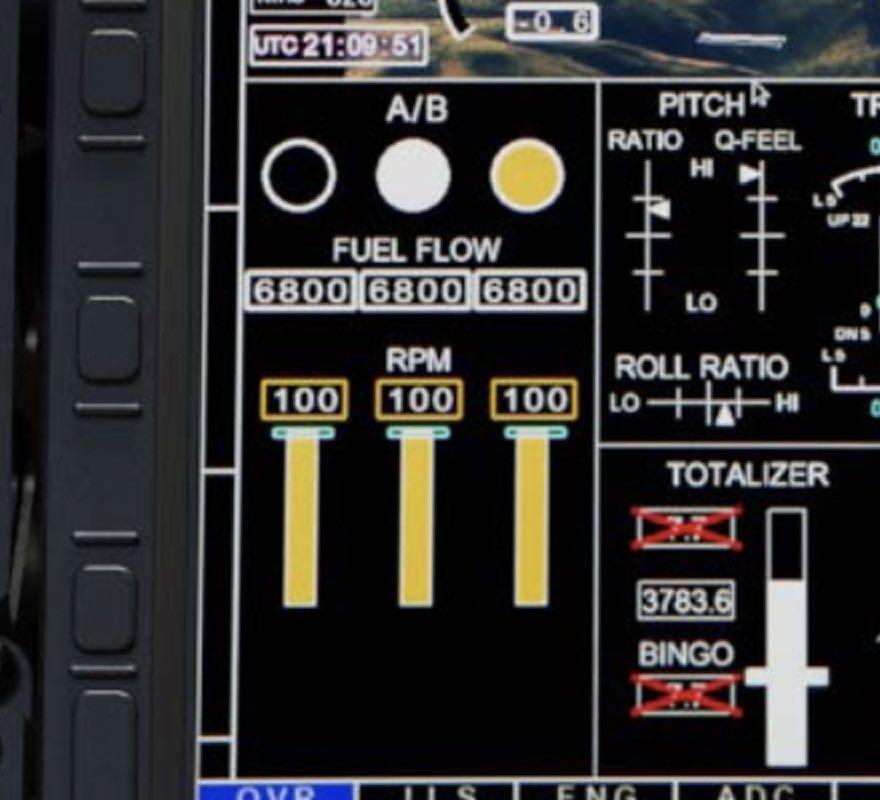

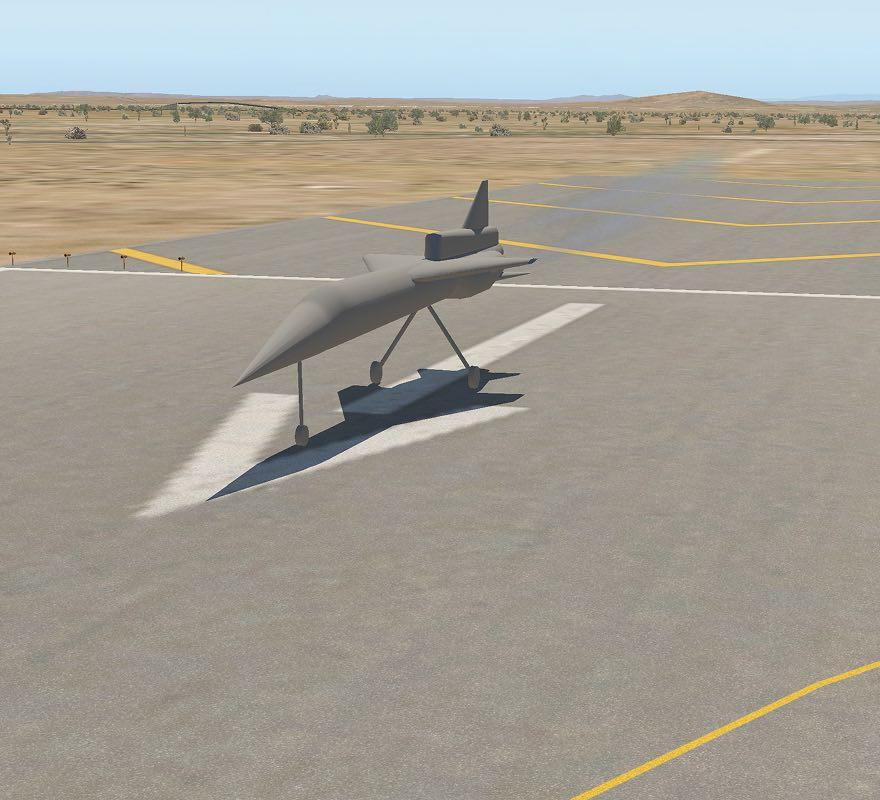

Boom’s visionary hardware—their aircraft—requires custom software to run. We helped Boom develop the onboard fuel system calculations for their XB-1 jet and also implemented key features for their flight simulation testing program.

Ensuring the safety of everyone onboard.

Fixing flight simulation errors to give test pilots an accurate feel.

Project Details

A new era of travel.

Boom is working to make the world dramatically more accessible. We’re excited to have helped further their mission to break down distance barriers and bring people together.